Automatic C200-300 Scaffolding Board Steel Roll Forming Machine

1.Main features of quickly change Scaffolding Board Steel Roll Forming Machine

The advantages of Scaffolding Board Steel Roll Forming Machine AUTOMATIC size-change type are as follows:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

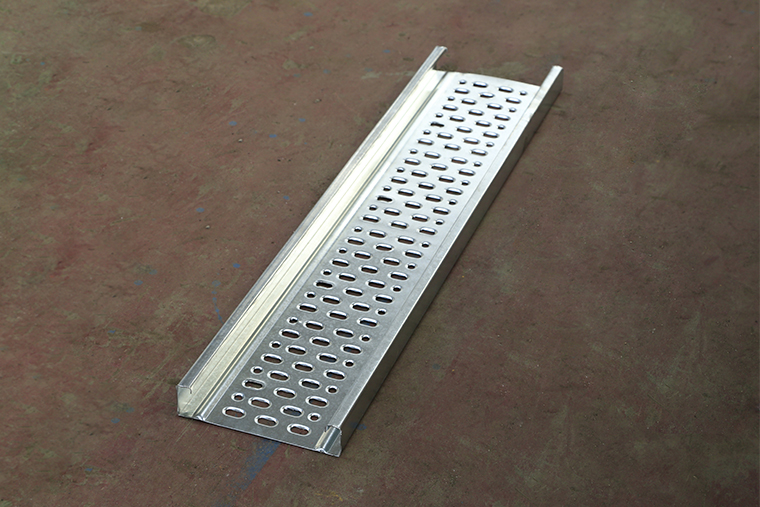

2.Detailed Images of C shaped Scaffolding Board Steel

Machine Parts

1) C200-300 Scaffolding Board Steel Roll Forming Machine leveling device

Brand: BMS Original: China

2) C200-300 Scaffolding Board Steel Roll Forming Machine puncher

Brand: BMS Original: China

Capacity:63 tons

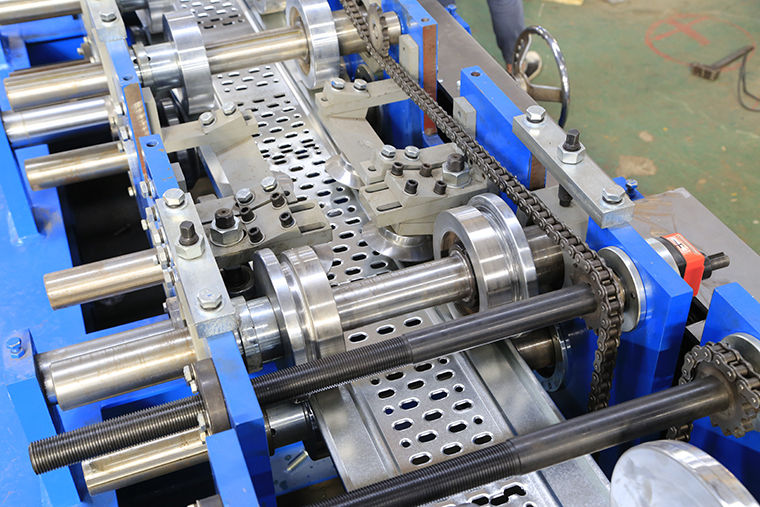

3) C200-300 Scaffolding Board Steel Roll Forming Machine roll forming mill

Brand: BMS Original: China

3) C200-300 Scaffolding Board Steel Roll Forming Machine PLC electronic control cabinet

Brand: BMS Original: China

3) C200-300 Scaffolding Board Steel Roll Forming Machine rollers

Brand: BMS Original: China

Rollers manufactured from high quality bearing steel GCr15, CNC lathes, Heat Treatment.

with black treatment or Hard-Chrome Coating for options.

With feeding material guide, body frame made from 400# H type steel by welding

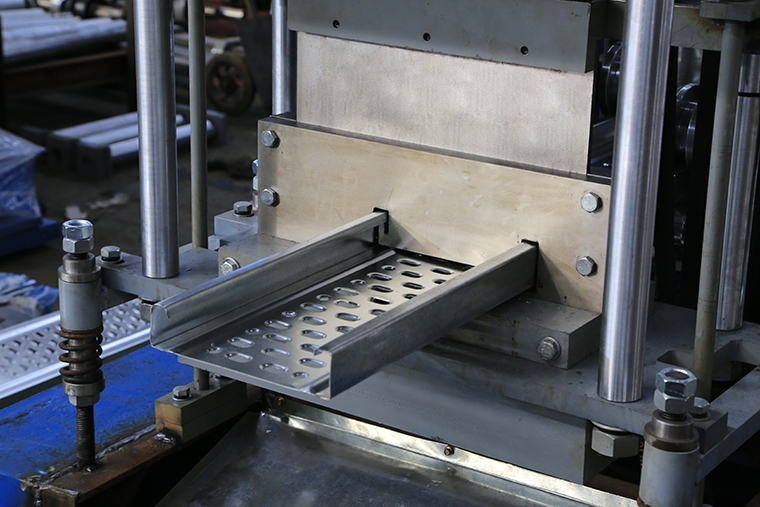

3) C200-300 Scaffolding Board Steel Roll Forming Machine post cutter

Brand: BMS Original: China

No need to change cutter for different size,

made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 30mm steel plate by welding

Pre-punching & Pre-cutting, stop to punch, stop to cut

hydraulic motor:7.5KW, Hydraulic pressure range: 0-16Mpa

4) C200-300 Scaffolding Board Steel product show

Brand: BMS Original: China