Please Click Here To View The Video

Octagon Pipe Roll Forming Machine

Profile

Technical Specifications

1. Decoiler, passive feeding, manually tense

2. Decoiler bearing, 5T

3. Main motor power,7.5KW(with gear reducer)

4. Forming stations, 21 stands

5. Main shaft diameter, ¢50mm

6. Flying saw, 3KW

7. Shear material, Cr12with quenching

8. Material thickness, 0.4-0.6mm

9. Coil width, 147mm

10. Cut to length, 10m±2mm

11. Roller material,GCR15 steel with quenching, hardness 58-620

12. Forming speed, 15m/min

13. Shear material, Cr12with quenching

14. Profile measure up to Chinese GBT/12755-91 standard

15. Frequency:American Danfoss

16. Computer adopt PLC control system,Mitsubishi FX-IS series

17. Computer operating board:Xinjie OP320A

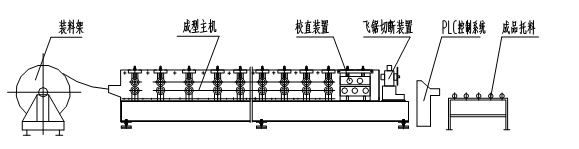

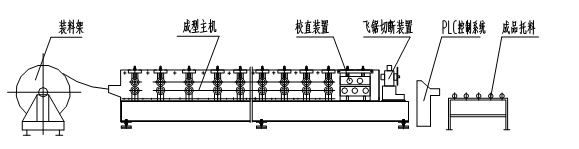

Work Flow

Uncoiler → Feed Guide Device → Roll Forming System → Straightening Device → Cut to Length→

PLC Control System → Exit Rack

2. Decoiler bearing, 5T

3. Main motor power,7.5KW(with gear reducer)

4. Forming stations, 21 stands

5. Main shaft diameter, ¢50mm

6. Flying saw, 3KW

7. Shear material, Cr12with quenching

8. Material thickness, 0.4-0.6mm

9. Coil width, 147mm

10. Cut to length, 10m±2mm

11. Roller material,GCR15 steel with quenching, hardness 58-620

12. Forming speed, 15m/min

13. Shear material, Cr12with quenching

14. Profile measure up to Chinese GBT/12755-91 standard

15. Frequency:American Danfoss

16. Computer adopt PLC control system,Mitsubishi FX-IS series

17. Computer operating board:Xinjie OP320A

PLC Control System → Exit Rack

Machine Components

1) Feed Guide Device

2) Roll Forming Machine

3) Cut to Length

4) PLC Control System

Control the quantity and cutting length automatically

Input the production data (Production Batch, pcs, Length, etc.) on the touch screen ,

It can finish the production automatically.

Combined with: PLC, Inverter, Touch Screen, Encoder, Independent Cabinet type etc

Combined with: PLC, Inverter, Touch Screen, Encoder, Independent Cabinet type etc

5) Product Show

After-Sale Service

1. The warranty is 24 months after the client receives the machine.

Within the 24 months, we will courier the replacement parts to the client free of charge

2. We offer technical support for the entire life of our machines

3. We can send our technicians to install and train the workers in the clients' factories with extra cost

Packing method

Main body of machine is naked and covered by plastic film (to protect of dust and corrosion), loaded into container

and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.