Please Click Here to View the Video

Quick Change CZ Purlin Roll Forming Machine

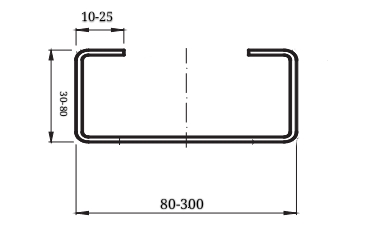

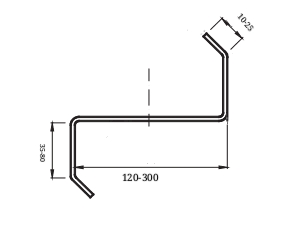

Profile Drawing

1. Produce purlins of different sizes without changing the rollers or pads.

2. Different sizes will not change.

3. Simple operation and low maintenance cost.

4. Unlimited size (any size within the machine range), simple size.

Machinery Order

1) CZ Purlin MachinePunching Ssystem

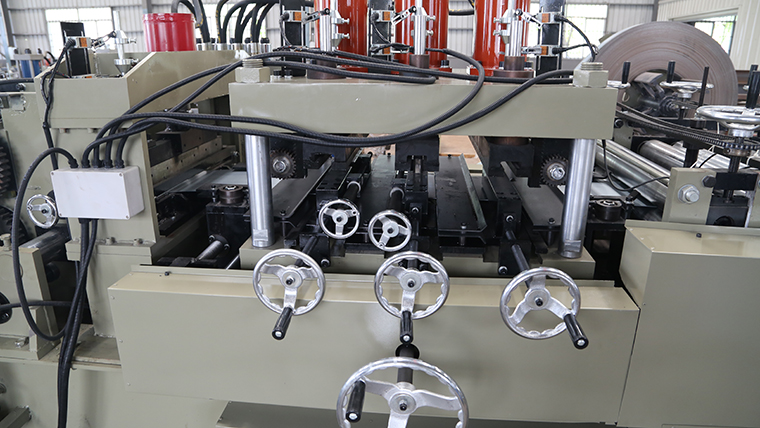

2) CZ Purlin Machine Roller

The rollers are made of high-quality bearing steel GCr15/die steel Cr12 (D3 steel), CNC lathe,

Heat treatment. With black treatment (Cr12 type roller) or

Hard chrome coating (for GCr15 roller), the machine has a long service life of 5 years.

With feed rail, the bracket is welded by 450#H-shaped steel

Brand: BMS Sample Text: China

Three cylinders (single hole 1 cylinder, double hole 2 cylinders).

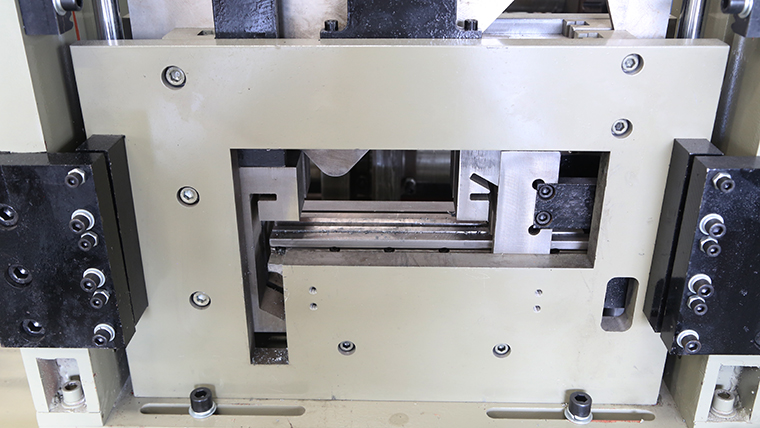

3) CZ Purlin Machine Post Cutter

No need to change tools of different sizes,

Made of Cr12 (D3 steel) made of high-quality mold steel with heat treatment.

The tool post is made of high-quality 30mm steel plate welded with pre-punching, pre-cutting,

stop-punching and stop-cutting. Hydraulic motor: 7.5KW, hydraulic range: 0-16Mpa

4) CZ Purlin Machine Positioning

C to Z purlin discoloration can be completed within 5-10 minutes.

5) CZ Purlin Decoiler

Manual decoiler

Un- power, manual control of the shrinkage and stop of the inner hole of the steel coil

Max. Feeding Width: 500mm, coil inner diameter range 470mm±30mm

Capacity: up to 5 tons

It is equipped with a 5 ton hydraulic decoiler

6) CZ Purlin Machine Export Frame

Other details of CZ purlin forming machine

Suitable for materials with thickness 1.0-3.0mm or 1.5-3.5mm

The shaft is made of 45# steel, shaft diameter=φ100mm, precision machined,

Motor drive, gear chain drive, with 16-step forming speed , 4-roll straightening

Main motor=22KW, frequency conversion speed regulation. Molding speed is about 15-20m/min

PLC Control System (Inverter brand:German Schneider Electric,Encoder brand:Japan Koyo/OMRON)

Interchange between C purlin and Z purlin: by manual changed, with following simple 3 steps

(It only takes 5-10 minutes to complete all):

a) Loosen the positioning pin;

b) Rotate the adjustment tool 180 degrees;

c) Fix the positioning pin.

But starting from C80-300 or Z140-300, the PLC system will automatically change the size:

Just adjust the required WEB, height and material width on the touch screen,

Then enter the required production data (batch, length, number of punching holes) on the touch screen.

The machine automatically completes the size change. No need to change wheels or shims or knives

Just like the traditional old-fashioned CZ purlin machine (it takes more than 45 minutes to change the production size each time).

Combination: PLC, inverter, touch screen, encoder, etc.

Fixed length tolerance≤±1.5 mm

Control voltage 24 V

After-Sale Service

1. The warranty is 24 months after the client receives the machine.

Within the 24 months, we will courier the replacement parts to the client free of charge

2. We offer technical support for the entire life of our machines

3. We can send our technicians to install and train the workers in the clients' factories with

extra cost

Packing method

Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into

container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.