Main Components

1.Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max.5Ton

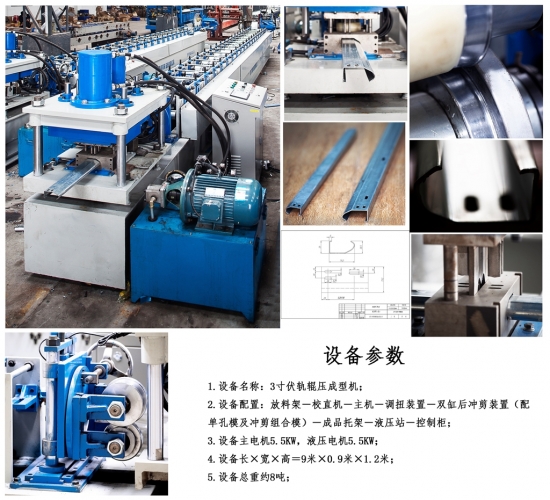

2.Cold Rolling Mills:

Material Thickness:2.0-2.5mm,Material Width:100mm,

With feeding material guide, body frame made from 450# H type steel by welding,Side wall thcikness: 18mm

Rollers manufactured from 45#, precision machined, hard Chrome Coated

Shafts manufactured from 45#,Diameter=φ70mm,precision machined

Motor Driving,Gear chain transmission, 21 steps to form

Main Motor=7.5KW , Frequency speed control 380V/50Hz/3Ph

Forming speed approx.5m/min

3.Hydraulic Cutting device

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting, use the same hydraulic motor drive

hydraulic motor:5.5KW, Hydraulic pressure range: 0-18Mpa

Cutting tool material: Cr12, Heat treatment

4.PLC Control System(Touch screen brand:German Schneider Electric,Inverter brand:Taiwan DELTA,Encoder brand:Japan Koyo)

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

5.Exit Rack Un-powered, two units

6.User's manual in English

Features of Door Frame Roll Forming Machine

Door Frame roll forming machine is used to produce profile for door.This product is widely used in many kinds of industrial factory, civilian buildings, and wall board for attached part product. It has advantage of pretty appearance, durable using and so on. It is producted continuously as roll forming machine instead using bending machine to make angel tile saving human resources, lower labor cost.

The complete door frame roll forming machine line includes decoiler, main machine, computer controlling system and run out tables. Our machines are equipped with a computer controlling system. We simply program the pieces and length we need in the computer and the ridge cap roll forming machine produces it automatically. The machines are easy to operate and running stable.

After-sale Service

1. The warranty of the roof panel forming machine is one year after the client receives the machine. Within the one year, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories.

Terms of trade

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: 60 days

3. Port of loading: port of Xiamen

4. Type of payment: T/T

5. Export: Australia, UK, Ireland, Mexico, Brazil ,Israel ,Dubai, Russia ,India, Taiwan, Singapore, Malaysia ,Thailand, Philippines, Myanmar ,Vietnam, South Africa, Mozambique, Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.